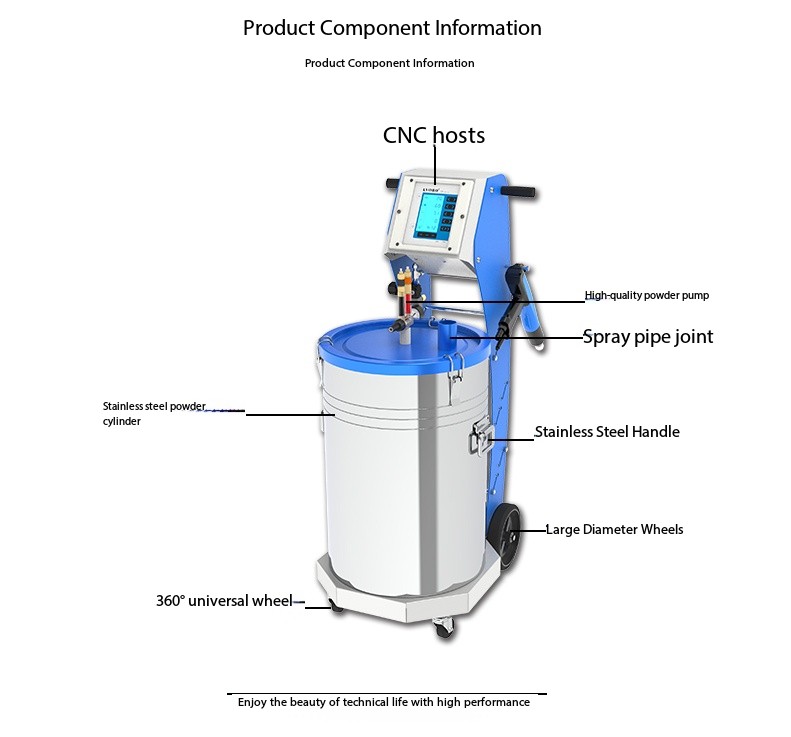

This is a Handheld Electrostatic Powder Spray Gun that works based on the principle of electrostatic adsorption. When the powder coating is ejected from the Spray Gun, the powder particles are negatively charged through the action of the high - voltage electrostatic field. And the coated workpiece is grounded, forming a positive potential difference. Under the traction of the electric field force, the negatively charged powder particles are quickly and evenly adsorbed to the surface of the workpiece, forming a flat and dense coating. Subsequently, after the heating treatment of the Curing Furnace, the powder coating melts, flows flat and solidifies, tightly combined with the surface of the workpiece.

The equipment comes with three formulas: plate surface coating, rework coating and dead corner surface coating, as well as 21 spraying procedures, enabling high-quality workpiece coating; it also features anautomatic qun cleaning function.

The control unit offers simple and clear operation for more convenient manaqement. Powder volume,atomization and cleaning adjustments are achieved via electronic touch, with the motherboard controllingthe inlet high-precision control valve to ensure accurate and constant air flow, thus quaranteeing precisepowder output and consistent spraying effects.

Item No :

BO-V26SOrder(MOQ) :

1PCSPrice :

$:689Product Origin :

ChinaColor :

customizableShipping Port :

xia menLead Time :

7 dayWeight :

30kgPayment :

T/T

High Efficiency Powder Rate: The advanced electrostatic generation device can produce a stable and strong electrostatic field, ensuring that the powder coating is adsorbed to the workpiece to the maximum extent. The powder utilization rate is significantly improved, effectively reducing the waste of paint and lowering the production cost.

Homogeneous Coating Quality: The carefully designed spray gun structure and the optimized airflow control system make the atomization effect of the powder coating excellent. The powder is ejected in a fine and uniform fan-shaped distribution. Whether it is a workpiece with a complex shape or a large-area plane, it can achieve a uniform coating thickness, with a smooth and even surface, without the phenomena of dripping and orange peel. The coating quality far exceeds that of the traditional spraying method.

1. Accurate Parameter Adjustment: Key parameters such as powder injection volume, atomization pressure, and electrostatic voltage can be accurately adjusted. The equipment parameters can be flexibly adjusted according to the material, shape, size, and coating process requirements of different workpieces to meet diversified production needs, and achieve operational convenience and adaptability.

2.Intelligent Fault Diagnosis: The built - in intelligent fault diagnosis system can monitor the running status of the equipment in real - time. Once a fault occurs, the fault code and cause are immediately and accurately displayed, facilitating maintenance personnel to quickly locate and solve the problem, shortening the equipment downtime and reducing maintenance costs.

The Spray Gun weighs only 460G and features an ergonomic design to achieve balance. Its delicacy and lightweight greatly reduce operation fatigue, making spraying easier. Considering a variety of superior characteristics, it is durable and easy to maintain. With an excellent powder coating rate and comprehensive spraying performance, it can improve the product surface layer.

The Low - Flow - Rate Powder Design allows the first powder rate to achieve the desired effect.

The powder is soft and uniform to ensure the uniform flow of the spray surface.

More powder can be achieved with only a small amount of compressed air.

Unique Design enables easy disassembly and connection.

BO-V09 electrostatic spray gun:

|

Parameter name |

Parameter details |

Parameter name |

Parameter details |

|

time to market |

In 2019 |

input voltage |

Single phase AC100-240V |

|

place of production |

China |

incoming frequency |

50-60Hz |

|

Charging mode |

Use AC AV220V |

interior input power |

60W |

|

Whether it is rechargeable |

deny |

Maximum output voltage of spray gun |

20-100 kV |

|

Duration of use |

Sustainable use |

Maximum output current of spray gun |

150uA |

|

Arc spray diameter |

15-280mm |

Spray powder adjustment range |

50-550 g/min |

|

Ejection distance |

300mm |

Powder particle size range |

10-150μm |

|

Powder bucket capacity |

40l |

air flow rate |

0-115L/min |

|

Single spray gun weight |

460g |

Single spray gun size |

Length 340mm × width 35mm × height 260 mm |

Powder quantity parameter:

|

Parameter name |

Air simulation display values |

Air flow (L/min) |

Powder output (g/min) |

|

Pressure, flow rate, powder quantity |

40 |

31 |

150 |

|

60 |

70 |

370 |

|

|

80 |

95 |

480 |

|

|

100 |

125 |

550 |

High voltage and current parameters:

|

Parameter name |

High pressure parameter (Kv) |

Host current parameters (Ma) |

Gugun current parameter (Ua) |

|

High voltage, main current, spray gun current |

20 |

450 |

25 |

|

40 |

500 |

60 |

|

|

60 |

580 |

80 |

|

|

80 |

700 |

110 |

|

|

100 |

790 |

130 |

Our hours

Monday - Saturday: 8:00 AM - 6:00 PM