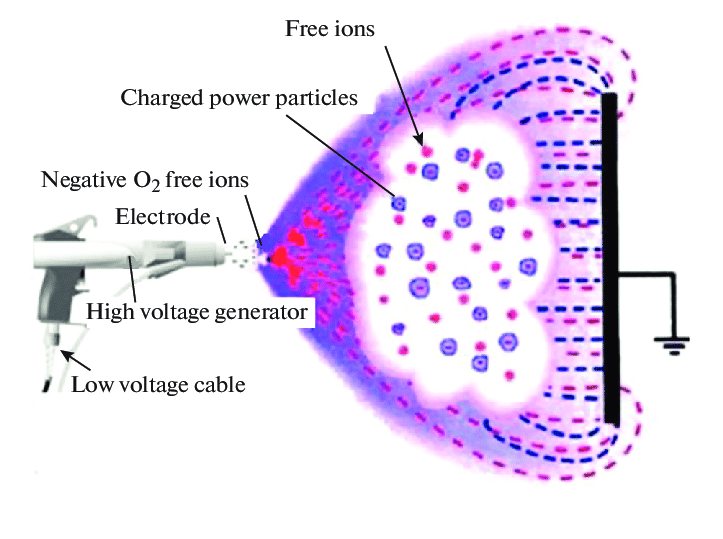

What is electrostatic powder coating? Electrostatic powder coating involves applying a powder coating to a substrate using electrostatic force, which then solidifies into a coating through heating. The powder coating typically consists of resin, curing agent, and pigments. During the spraying process, the powder is charged by a spray gun and then adsorbed onto a metal or other substrate with opposite charges by an electric field. After the spraying is complete, the substrate is heated in an oven, causing the powder to melt and solidify, resulting in a strong, durable coating.

Advantages and Application Fields of Electrostatic Powder Coating

Advantages:

-Environmental friendliness: Electrostatic powder coating does not produce volatile organic compounds (VOCs), reducing environmental pollution.

-High efficiency: The powder is almost 100% utilized during the spraying process, with minimal waste.

-Strong durability: The coating offers excellent resistance to corrosion, wear, and high temperatures.

-Wide adaptability: It can be applied to various materials, including metals and plastics, particularly steel and aluminum alloys.

-No solvent pollution: The absence of solvents reduces the risk of harm to the environment and operators.

Application Fields:

-Home appliance industry: Used for painting the exteriors of home appliances, such as refrigerators and washing machines.

-Automotive industry: Primarily used for painting body parts and chassis.

-Furniture industry: For painting metal components of furniture to prevent rust and enhance appearance.

-Construction industry: Surface treatment for components like doors, windows, window frames, and steel structures.

-Metal products: Anti-corrosion coatings for steel and aluminum products.

Introduction to Common Spraying Equipment: Electrostatic powder spraying requires a comprehensive equipment system. Common equipment includes:

-Spray Gun: The spray gun is the core device of electrostatic spraying, charging the powder coating with a high-voltage power supply. It comes in handheld and automatic types, suitable for various production scenarios.

-Electrostatic Generator: The electrostatic generator generates an electric field, which charges the powder coating. It connects to the spray gun to control the charge distribution and powder quantity during the spraying process.

-Powder Supply System: This system includes a powder hopper and a conveying system, which supply powder to the spray gun. Common types include pneumatic and electric systems.

-Curing Oven: The curing oven is a heating device used after spraying to heat the coated object, causing the coating to melt and solidify, forming a durable layer.

-Air Compressor System: This system provides the compressed air needed during the spraying process, helping the powder to be sprayed out of the spray gun and adhere to the substrate surface.

Next time we'll talk about pre-spray preparation

Our hours

Monday - Saturday: 8:00 AM - 6:00 PM