Commercial Small Electric Sieve Powder Machine Powder Screening Equipment Customized

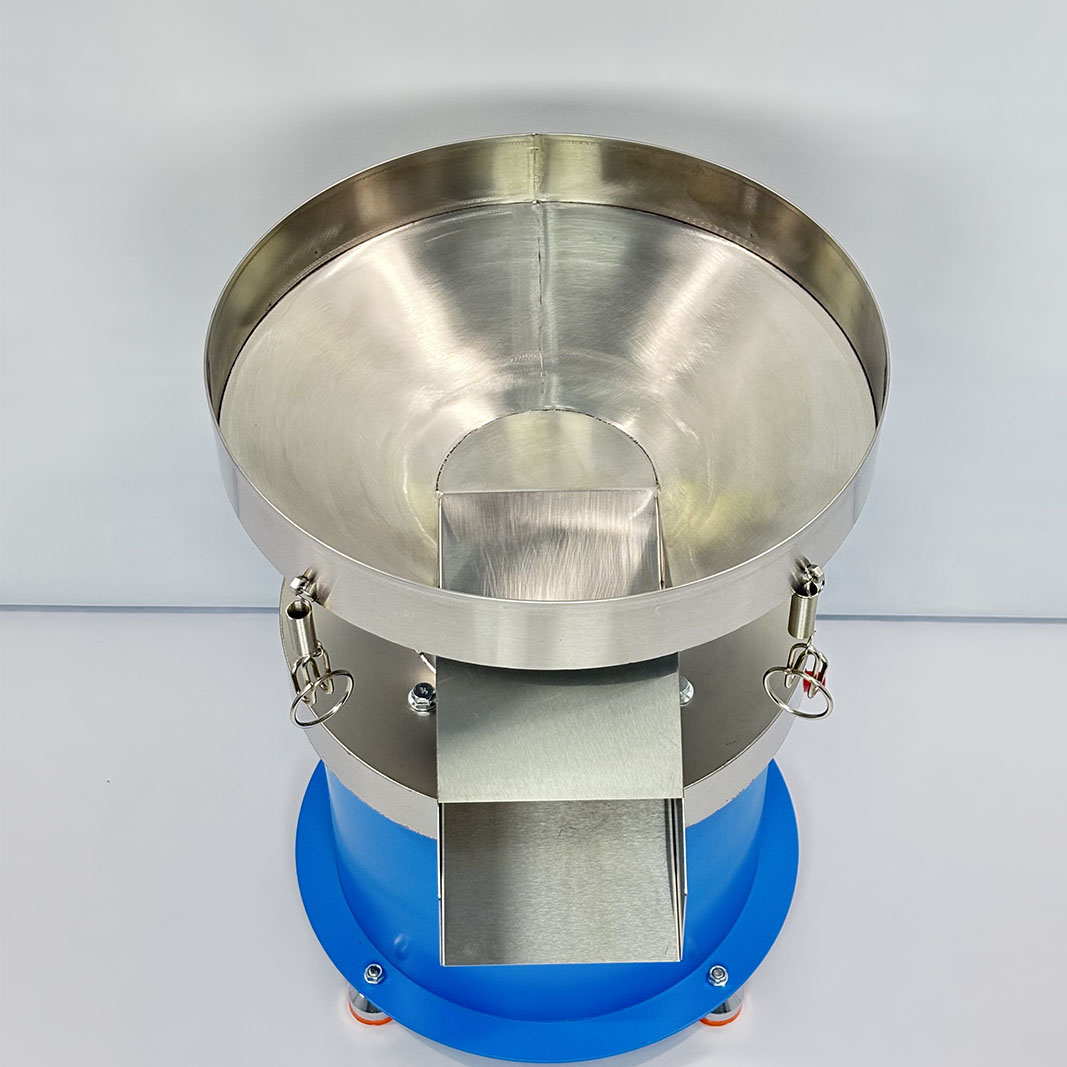

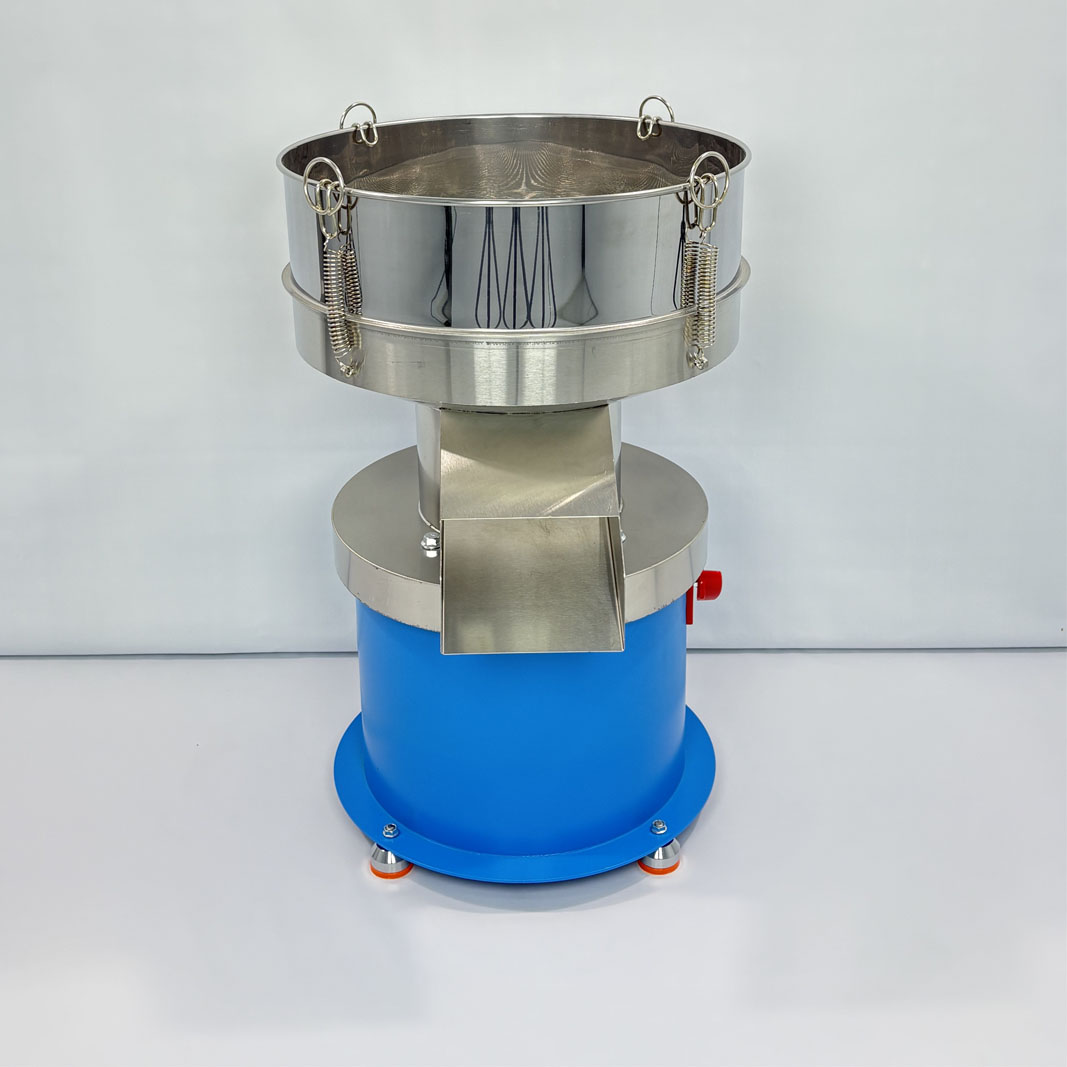

Small Circular Vibrating Screen Machine is an efficient and practical electric screening equipment. With its compact circular design and accurate screening ability, it can efficiently screen out foreign bodies, filter impurities, and grade materials, ensuring high - quality products. It is widely used to meet a variety of material - processing requirements in different industries. Equipped with an advanced vibration system, it can generate a stable and appropriate vibration frequency, facilitating the quick and even movement of materials on the screening mesh. This enables an efficient screening process and effectively separates materials with different particle sizes. The screening mesh has high accuracy, and screens with different pore sizes can be customized according to specific needs to precisely select materials that meet specific particle - size requirements, thus ensuring the consistency of product quality.

Item No :

BO-27BOrder(MOQ) :

1PCSPrice :

$:180Product Origin :

ChinaColor :

customizableShipping Port :

xia menLead Time :

30 DaysWeight :

23kgPayment :

T/T

Technical Parameter

1. Screen Specification: The diameter is 400mm, and the screen aperture can be flexibly selected within the range of 0.1mm - 5mm to meet the screening requirements of different materials.

2. Vibration Frequency: The range is generally 1,400 times/minute.

3. Processing Capacity: It varies according to different material types, particle sizes and screening requirements. The approximate processing capacity is between 5 - 100 kg/hour.

4. Motor Power: The vibration motor power is 0.35kW, to ensure stable and sufficient power for the vibration screen while taking into account energy - saving needs.

Process:

The overall manufacturing process is exquisite. All parts are carefully processed and assembled. The surface is smooth, ensuring the smooth operation of the equipment and reducing material residue and blockage phenomena.

Material and Process

Material: Main Contact Surface Material: The main contact surface material is 304 Stainless Steel. It exhibits good corrosion resistance and high strength, being suitable for contact with all kinds of materials. Notably, it is highly appropriate for industries like food and medicine, which have strict health requirements.

Screen Material: The screen is made of high - strength, high - precision stainless - steel wire that is woven. It features a uniform mesh and good wear resistance, ensuring long - term screening accuracy.

Efficient Liquid - Powder Separation Feature

Unique Design for Efficiency: The equipment has a unique design that enables efficient separation of liquid and powder. This design optimizes the separation process, making it both high - efficiency and convenient.

Powerful Screening Force: It comes with a strong power screening force. This force ensures that the liquid and powder are separated effectively, contributing to the overall high - performance operation of the separation process.

Technical Parameter:

|

The parameter name |

Parameter details |

The parameter name |

Parameter details |

|

Manufacturing ground |

China |

Time to market |

In 2022 |

|

Product name |

sifting machine |

Product model |

BO-27B |

|

Input voltage |

AC110V / 220V / 380V is optional |

Interiorinput power |

350W |

|

Shake frequency |

And 1,400 beats / min |

Screen diameter |

400mm |

|

Sieve mesh number |

Optional 8-200 entries |

Host size |

D520×W430×H515mm |

|

Description of mesh number |

||

|

Mesh number |

||

|

The larger the number of mesh, the smaller the material particles: |

||

|

Screen mesh number reference |

||

|

food |

Grain flour 20-50 mesh |

Chinese medicine powder 60-80 mesh |

|

Filter soy milk for 50-100 mesh |

Thread powder 100-140 mesh |

|

|

Flour 40-60 mesh |

Pearl powder 120-180 mesh |

|

|

Douhua douzhe filter 60-140 mesh |

|

|

|

industrial |

Spray plastic powder 120-140 mesh |

Ceramic mud 50-60 mesh |

|

3D printing 316 powder 300-500 mesh |

Cellulose 80-100 mesh |

|

|

Ceramic glaze material 60-80 mesh |

Paint 100-200 mesh |

|

|

Lead powder 60-120 mesh |

Beanstalk filter 140-180 mesh |

|

|

Screen size and mesh comparison table |

|||||

|

Mesh number |

Aperture (mm) |

Mesh number |

Aperture (mm) |

Mesh number |

Aperture (mm) |

|

2mesh |

12.5 |

45mesh |

0.4 |

220mesh |

0.065 |

|

3mesh |

8 |

50mesh |

0.355 |

240mesh |

0.063 |

|

4mesh |

6 |

55mesh |

0.315 |

250mesh |

0.061 |

|

5mesh |

5 |

60mesh |

0.28 |

280mesh |

0.055 |

|

6mesh |

4 |

65mesh |

0.25 |

300mesh |

0.05 |

|

8mesh |

3 |

70mesh |

0.224 |

320mesh |

0.045 |

|

10mesh |

2 |

75mesh |

0.2 |

325mesh |

0.043 |

|

12mesh |

1.6 |

80mesh |

0.18 |

340mesh |

0.041 |

|

14mesh |

1.43 |

90mesh |

0.16 |

360mesh |

0.04 |

|

16mesh |

1.25 |

100mesh |

0.154 |

400mesh |

0.0385 |

|

18mesh |

1 |

110mesh |

0.15 |

500mesh |

0.0308 |

|

20mesh |

0.9 |

120mesh |

0.125 |

600mesh |

0.026 |

|

24mesh |

0.8 |

130mesh |

0.112 |

800mesh |

0.022 |

|

26mesh |

0.71 |

140mesh |

0.105 |

900mesh |

0.02 |

|

28mesh |

0.68 |

150mesh |

0.1 |

1000mesh |

0.015 |

|

30mesh |

0.6 |

160mesh |

0.096 |

1800mesh |

0.01 |

|

32mesh |

0.58 |

180mesh |

0.09 |

2000mesh |

0.008 |

|

35mesh |

0.5 |

190mesh |

0.08 |

2300mesh |

0.005 |

|

40mesh |

0.45 |

200mesh |

0.074 |

2800mesh |

0.003 |

Our hours

Monday - Saturday: 8:00 AM - 6:00 PM