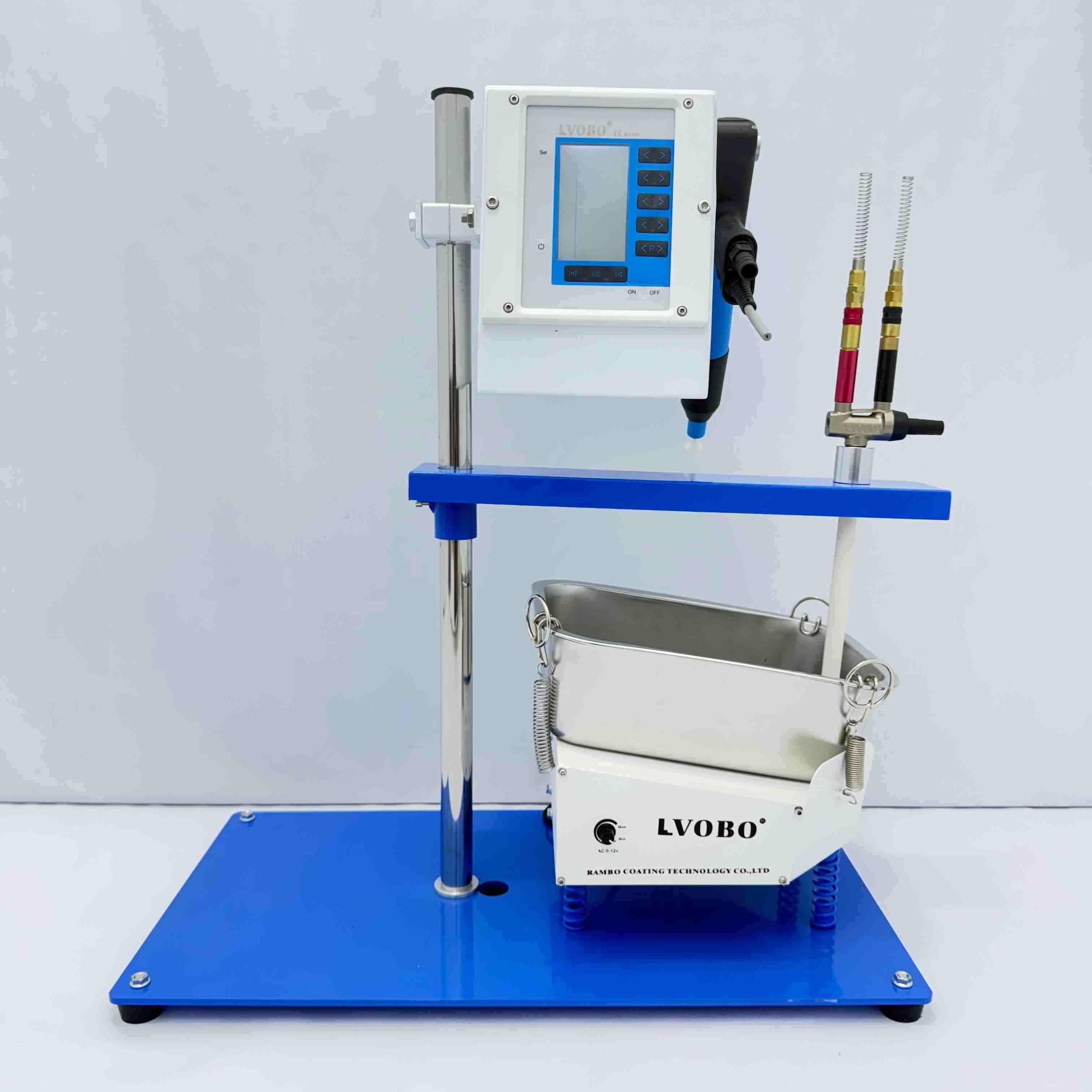

Laboratory powder electrostatic spraying machine vibration powder feeding bucket

Powder static spray gun is a powder spraying tool specially designed for small laboratories. It is suitable for a small amount of medicine, trace powder spraying, multi-layer powder spraying experiment, metal surface material anti-corrosion test, a small amount of spraying color change DIY coating and other laboratory powder spraying needs.

Compared with air fluidized powder supply, vibration powder supply is more environmentally friendly. Powder does not fly around, which is more suitable for dust-free operation in laboratory

Item No :

BO-V09YZOrder(MOQ) :

OnePrice :

$557Product Origin :

Quanzhou, Fujian provinceColor :

customizableShipping Port :

XiamenLead Time :

7dayWeight :

22kgPayment :

T/T

characteristic :

1. Compact and light: easy to handle and move flexibly in the laboratory, suitable for small workpieces or small area spraying sample.

2. High powder utilization rate: The powder cup design on the vibrating plate loosens the powder through vibration to ensure smooth powder supply, which is more environmentally friendly than fluidized bucket. The powder does not dust and the powder can be changed easily.

3. Multiple adjustment functions: powder quantity 50-280g/min, static voltage 10-100kV adjustable, to meet different powder spraying requirements.

4. Good electrostatic effect: it can make the powder fully charged, produce strong electrostatic adsorption force, ensure that the powder is evenly and firmly attached to the coating surface, improve the spraying quality.

apply :

1. Material research: used for surface modification of new materials, such as spraying functional powder coating on the surface of metal, ceramic and polymer materials to improve the surface properties of materials, such as wear resistance, corrosion resistance, electrical conductivity, etc.

2. Product development: In the new product development stage, small batch spraying samples are carried out to quickly verify the appearance, performance and process feasibility of products, such as early research and development of electronic product shell and auto parts. 3. Teaching experiment: Materials science, chemical engineering, mechanical engineering and other related majors in universities and research institutes are used for teaching experiment to let students understand the principle and process of electrostatic spraying.

BO-V09 laboratory electrostatic spray gun:

|

Parameter name |

Parameter details |

Parameter name |

Parameter details |

|

time to market |

In 2022 |

input voltage |

Single phase AC100-240V |

|

place of production |

China |

incoming frequency |

50-60Hz |

|

Charging mode |

Use AC AV220V |

interiorinput power |

40W |

|

Whether it is rechargeable |

deny |

Maximum output voltage of spray gun |

20-100 kV |

|

Duration of use |

Sustainable use |

Maximum output current of spray gun |

150uA |

|

Arc spray diameter |

15-280mm |

Spray powder adjustment range |

50-280 g/min |

|

Ejection distance |

300mm |

Powder particle size range |

10-150μm |

|

Powder bucket capacity |

250ml 500ml |

air flow rate |

0-130L/min |

|

Single spray gun weight |

550g |

Single spray gun size |

Length 340mm × width 70mm × height 360 mm |

Powder quantity parameter:

|

Parameter name |

Air simulation display values |

Air flow (L/min) |

Powder output (g/min) |

|

Pressure, flow rate, powder quantity |

40 |

49 |

140 |

|

60 |

100 |

200 |

|

|

80 |

130 |

250 |

|

|

100 |

145 |

280 |

High voltage and current parameters:

|

Parameter name |

High pressure parameter (kv) |

Host current parameters (ma) |

Gugun current parameter (ua) |

|

Parameter name |

Spray gun high voltage kv |

The distance is 25MM and the main current is ma |

The distance is 25MM spray gun currentua |

|

High voltage, main current, spray gun current |

20 |

450 |

25 |

|

40 |

500 |

60 |

|

|

60 |

580 |

80 |

|

|

80 |

700 |

110 |

|

|

100 |

790 |

130 |

Operation convenience and humanized design

1. Simple operation interface: The equipment is equipped with an intuitive and simple operation panel, and the parameters are obvious at a glance. The operators only need to have a simple training, can easily get on the operation of the equipment, quickly master the operation method of the equipment, and realize accurate control.

2. Quick color change system: For the needs of multi-color spraying, an efficient quick color change system can be selected to complete the switching and cleaning of powder coating in a short period of time, greatly improving production efficiency and reducing the waste of coating and time cost in the process of color switching.

3. Intelligent fault diagnosis: The built-in intelligent fault diagnosis system can monitor the operation status of the equipment in real time. Once a fault occurs, the fault code and cause can be displayed accurately immediately, so that the maintenance personnel can quickly locate and solve the problem, shorten the downtime of the equipment, and reduce the maintenance cost.

Our hours

Monday - Saturday: 8:00 AM - 6:00 PM