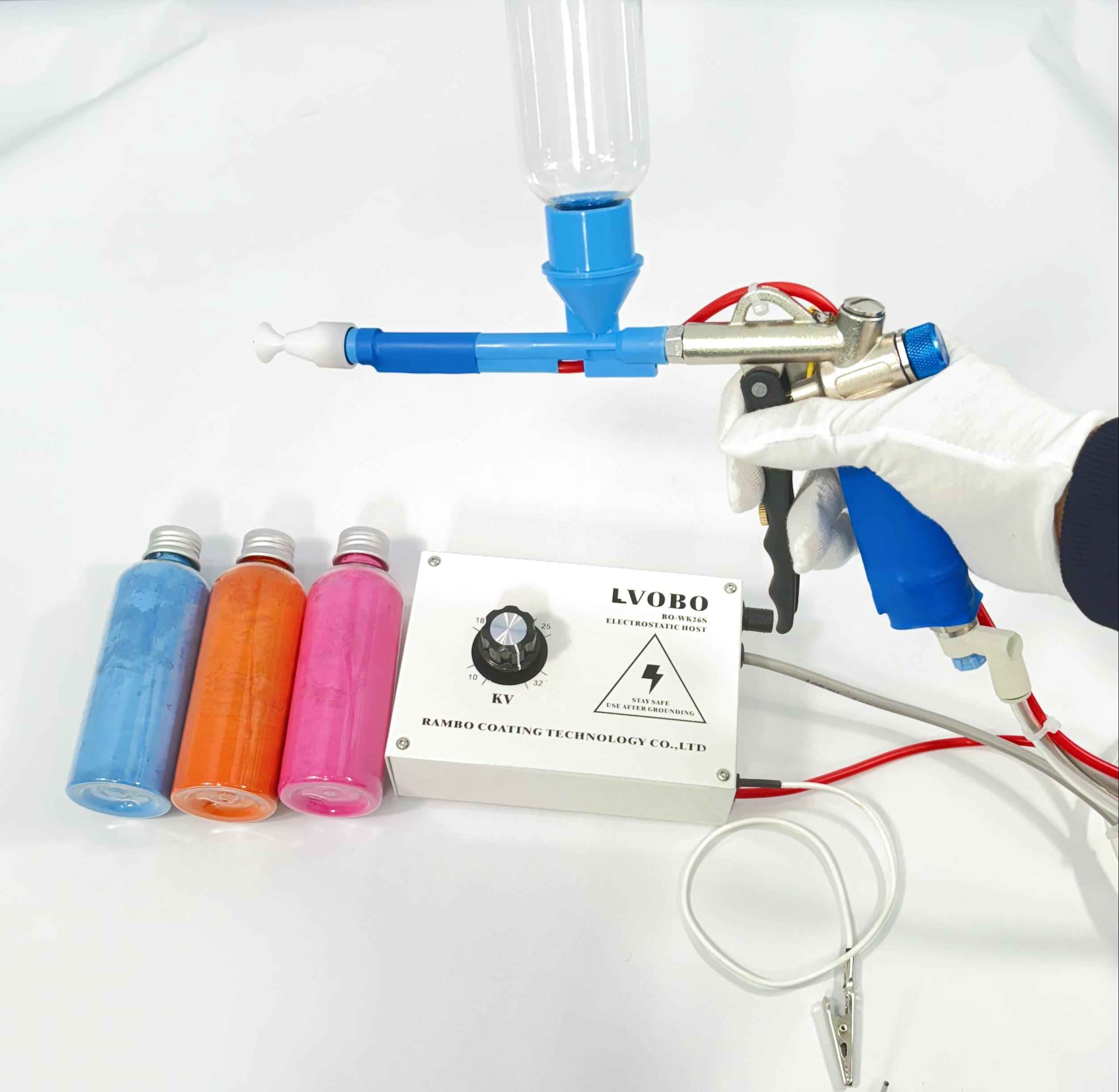

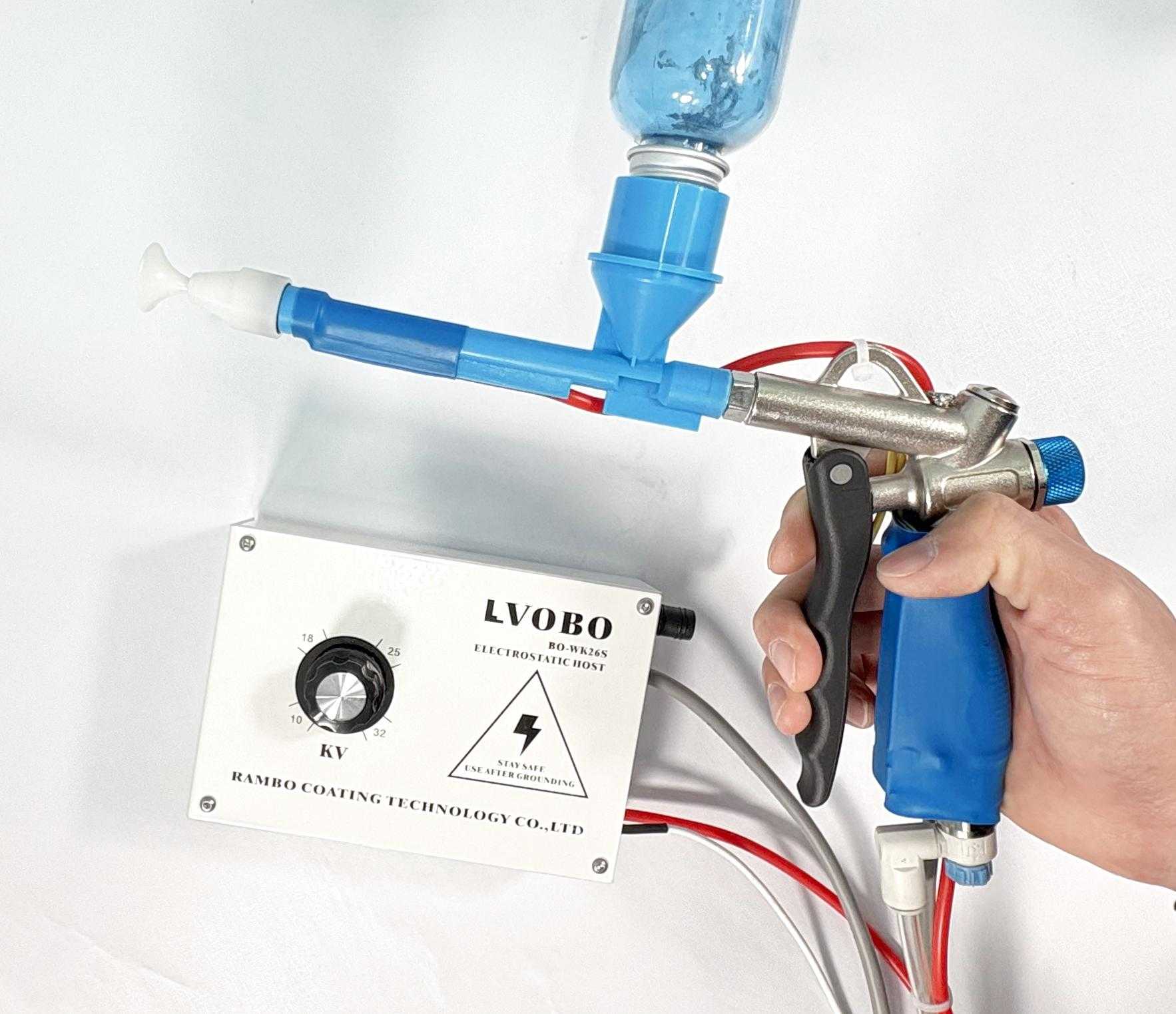

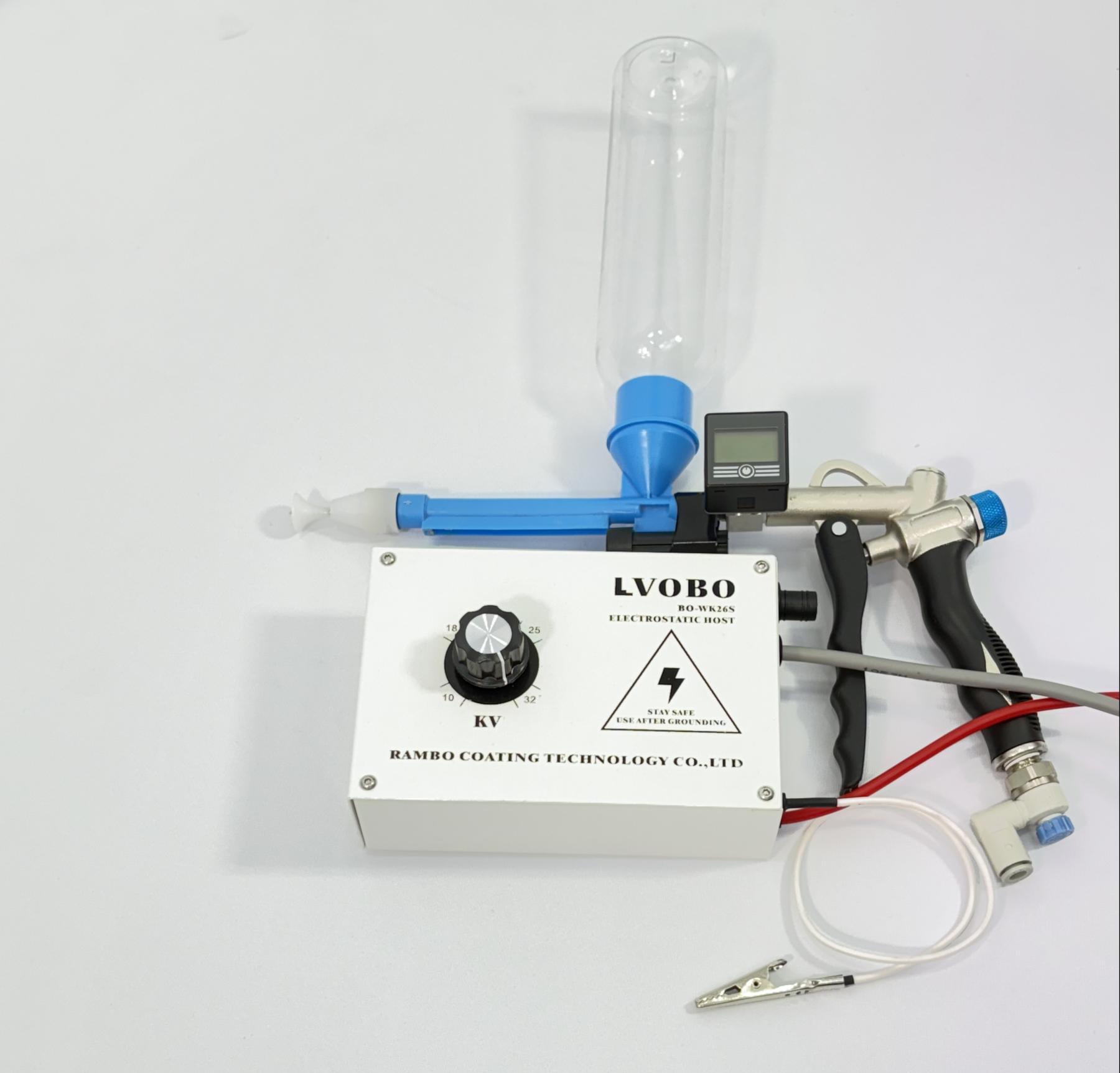

This small electrostatic spray gun is designed for laboratory small electrostatic powder spraying tools, a small amount of powder spraying, powder multi-layer spraying experiment, materials on the metal surface corrosion test, small amount of color change DIY electrostatic spraying and other laboratory powder spraying requirements. Small portable handheld operation and flexible movement in the laboratory, using DC12V lithium battery power supply to carry out, suitable for small workpiece or small area of spraying proofing.

Item No :

BO-VX26WOrder(MOQ) :

1PCSPrice :

$:138Product Origin :

ChinaColor :

customizableShipping Port :

xia menLead Time :

30 DaysWeight :

5kgPayment :

T/T

1, small and light: easy to hand operation and flexible movement in the laboratory, with DC12V lithium battery is easy to carry out, suitable for small workpiece or small area of spraying proofing.

2, high powder utilization rate: electrostatic adsorption to reduce powder drift, powder cup is close to the nozzle, with 4.8mm small powder pipeline can be adjusted to 35g / min, suitable for trace powder spraying.

1.Various adjustment functions: the amount of powder is 35-220g / min, and the electrostatic voltage of 5-32 kV can be adjusted to meet different powder spraying requirements.

2. good electrostatic effect: it can make the powder fully charged, produce strong electrostatic adsorption force, ensure that the powder is evenly and firmly attached to the surface of the coating, and improve the spraying quality.

1, material research: used for surface modification of new materials, such as spraying functional powder coating on the surface of metal, ceramics, polymer materials, improve the surface properties of materials, such as wear resistance, corrosion resistance, electrical conductivity, etc.

1. Teaching experiment: material science, chemical engineering, mechanical engineering and other related majors in universities and scientific research institutions are used for teaching experiment, so that students can understand the principle and process of electrostatic spraying.

1. Product research and development: In the new product development stage, quickly verify the product appearance, performance and process feasibility, such as the early research and development of electronic product shell, auto parts, etc.

Technical parameter table:

Small spray gun:

|

Parameter name |

Parameter details |

Parameter name |

Parameter details |

|

time to market |

In 2024 |

place of production |

China |

|

Charging mode |

DC12V lithium battery |

interiorinput power |

3W |

|

Whether it is rechargeable |

yes |

Maximum output voltage of spray gun |

10-32 kV |

|

Duration of use |

30min |

Maximum output current of spray gun |

120uA |

|

Arc spray diameter |

15-280mm |

Spray powder adjustment range |

20-220 g/min |

|

Ejection distance |

150mm |

Powder particle size range |

10-150μm |

|

Powder bucket capacity |

150ml |

air flow rate |

0-27L/min |

|

Single spray gun weight |

240g |

Single spray gun size |

Length 195mm × width 40mm × height 290 mm |

Powder parameters:

|

The parameter name |

Gun air pressure (kg) |

Air Flow Rate (L/min) |

Powder yield (g / min) |

|

Air pressure, flow rate, and powder amount used |

0.5 |

5 |

35 |

|

0.8 |

8 |

60 |

|

|

1.0 |

10 |

75 |

|

|

1.5 |

12 |

80 |

|

|

2.0 |

15 |

91 |

|

|

2.5 |

18 |

123 |

|

|

3.0 |

21 |

150 |

|

|

3.5 |

23 |

190 |

|

|

4.0 |

26 |

220 |

High-voltage and current parameters:

|

The parameter name |

Spray gun high pressure |

Host current parameters |

Spray gun current parameters |

|

|

10kv |

100ma |

26ua |

|

18kv |

160ma |

50ua |

|

|

25kv |

200ma |

55ua |

|

|

31kv |

300ma |

75ua |

Our hours

Monday - Saturday: 8:00 AM - 6:00 PM